The Hicof AMACODER is a revolutionary serialization machine with tamper evident labeling, based on an intermittent box transport mechanism. The line, made with Swiss craftsmanship is only 1.08 m long, providing high quality output and low reject rates.

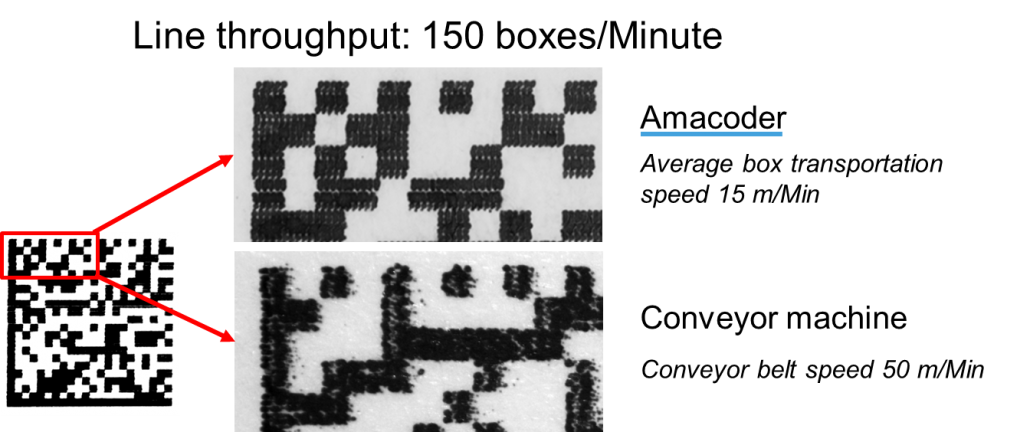

Automatic cartoner lines operate either intermittent (indexed) or continuous. Continuous lines are capable of very high box throughput but are expensive and large. On the other hand, intermittent running cartoner machines are compact, cost effective but usually limited to a speed of 150 packs/min what is sufficient for most applications. As next process step, a legally mandated pharma serialization code is inline printed and for European markets a tamper evident label is applied on the product package.

Hicof is the first and only company, offering Serialization Machine with Tamper Evident Labeling which work intermittently. The unique, patent applied concept of the Hicof AMACODER is the use of pushers for transporting the boxes through the machine. Therefore, no conventional conveyor is used.

It works as follows: Boxes, coming from an upstream machine e.g. a cartoner or checkweigher, are transported by a conveyor to the in-feed plate of the AMACODER. A feeding pusher from the side shifts incoming boxes laterally onto the transport slide, in front of a second pusher which shifts the boxes through the AMACODER. After a stroke of the pusher, it retracts to its initial position, leaving room for new boxes, introduced from the side. This cycle is repeated permanently, resulting in an indexed, highly controlled movement of the stack of boxes through the machine.

The AMACODER-TE is a proven Serialization Machine with Tamper Evident Labeling with a wide range of options available. Reaching from checkweigher integration to various in-feed and out-feeding options.

The AMACODER Serialization machine with tamper evident labeling delivers a very high coding quality as shown in the image below.

The reason for this high coding quality is as follows:

The AMACODER-TE75 is the most versatile model offering highest flexibility for Box sizes ranging from 55 to 300mm. Thereby the AMACODER-TE75 is offering the shortest overall footprint of all AMACODER models. This makes the AMACODER-TE75 the ideal machine for manual packaging operations.

The AMACODER-TE150 is the ideal machine to integrate into automatic packaging lines. Offering economic design with fast changeover times. The AMACODER-TE150 is ideally combined with the AMAPACKER-S150 to offer seamless serialization with aggregation.

The AMACODER-TE300 marks the top of the line AMACODER Model which offers superior speed and product control even for critical applications.

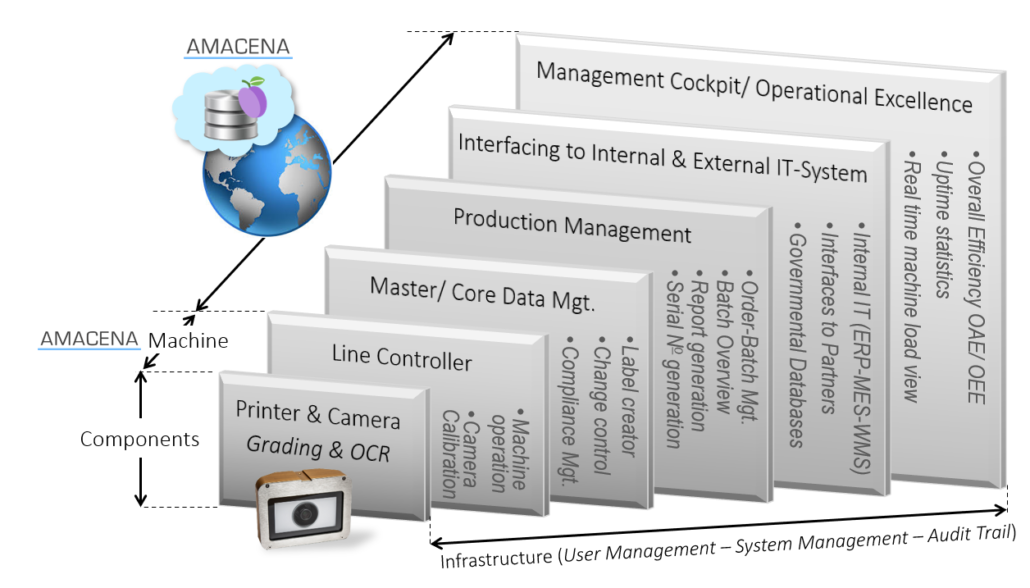

Hicof Amacena features a build-in web based label creator to create and adjust all print layouts for AMACODERS, and all connected tertiary label printers. The label creator allows GMP compliant change control of all label parameters across the enterprise.

Hicof AMACENA is a uniform system covering all serialization related topics in the enterprise. The solution works as monoblock which allows the customer to use the same user interfaces across AMACENA. This reduces efforts in training and operations.

The HICOF Machines offer in combination with AMACENA an integrated IT-backbone, starting at machine level from the devices as printers, cameras and sensors up to data interfaces of governmental servers. In case of an issue, our experts have instantaneously access through remote access to all relevant parameters across all IT-servers down to the PLC, allowing a seamless and immediate support. This is the opposite of the conventional ISA-95 environment with several software and machine suppliers in which each service engineer has only access to his fraction of data, making a comprehensive root cause analysis extremely cumbersome as he has to synchronize with other involved vendors.

Hicof solves the issue by offering One System, One Supplier, One Responsibility!