Our pharmaceutical serialization solution offers complete traceability, from unit-level coding to full aggregation, ensuring regulatory compliance and patient safety. Designed and manufactured in Switzerland, our integrated system eliminates the complexities of third-party interfaces. With in-house developed hardware and software, we guarantee seamless operation and reliability. Trust us to safeguard your products and streamline your supply chain.

In today’s pharmaceutical industry, a Pharma Serialization Solution is not just a regulatory necessity—it’s a strategic tool for securing your supply chain and ensuring patient safety. With counterfeit drugs on the rise and global regulations constantly evolving, pharmaceutical companies need a comprehensive system to track, verify, and protect every product.

Hicof’s Pharma Serialization Solution offers an end-to-end approach that covers everything from single unit coding to full aggregation. Developed and manufactured entirely in Switzerland, our solution guarantees exceptional quality, precision, and reliability. With our fully integrated machines and software—designed under one roof—Hicof eliminates the interface challenges often encountered with third-party systems.

Serialization assigns a unique identifier to every unit of a prescription drug, typically encoded as a 2D data matrix barcode. This identifier creates a digital “fingerprint” for each package, ensuring full traceability throughout the supply chain—from the manufacturing floor to the patient’s hands.

As the pharmaceutical industry faces increasing pressure to improve transparency and accountability, Hicof’s solution stands as a critical asset for any organization looking to safeguard its products and reputation.

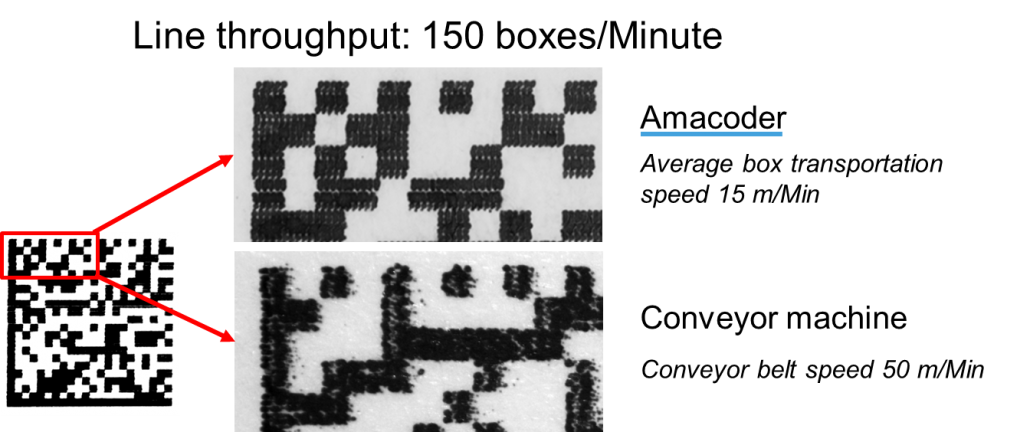

The Amacoder delivers a very high coding quality as shown in the image.

The reason for this high coding quality is as follows:

Hicof is uniquely positioned in the market due to several strategic advantages that set us apart:

Fully Integrated Design: Our machines and software are designed and developed by the same company. This unified approach means there’s no need for separate interfaces or third-party integrations—everything works seamlessly together. The result is a plug-and-play system that significantly reduces implementation time, minimizes errors, and enhances overall system reliability.

Swiss Engineering Excellence: Every component of our solution is 100% designed and built in Switzerland. Renowned for precision engineering and high-quality manufacturing, Swiss design ensures that our serialization technology meets the highest international standards. This dedication to quality means you can rely on Hicof for robust, long-lasting serialization solutions.

Comprehensive Range of Solutions: Hicof offers the full spectrum of serialization technologies—from single unit coding for small-scale production to full aggregation solutions for high-volume operations. Our complete range of necessary machines and software means that no matter the complexity of your needs, Hicof has you covered with an integrated, end-to-end solution.

Streamlined Implementation: Because our systems are fully integrated and designed in-house, the implementation process is smoother and faster. There is no need to synchronize disparate systems or troubleshoot compatibility issues. This results in reduced downtime and lower total cost of ownership.

As the pharmaceutical industry faces increasing pressure to improve transparency and accountability, Hicof’s solution stands as a critical asset for any organization looking to safeguard its products and reputation.

Hicof AMACENA features a build-in web based label creator to create and adjust all print layouts for AMACODERS, and all connected tertiary label printers. The label creator allows GMP compliant change control of all label parameters across the enterprise.

At Hicof, the integration between hardware and software is at the core of our development philosophy. Our engineers work side by side during every stage of development to ensure that every component communicates flawlessly with the other. This integration brings several benefits:

Automated Workflows Our system automates routine tasks such as data entry, reporting, and compliance checks. This automation reduces human error and frees up your staff to focus on more strategic activities.

User-Friendly Interface Our intuitive user interface minimizes the learning curve, allowing your team to quickly adapt to the new system. Clear dashboards, detailed reports, and easy navigation mean that everyone—from operators to managers—can work more efficiently.

Our manufacturing process follows stringent Swiss quality standards. Every machine is produced under strict quality control measures, ensuring that each unit delivered to you is built to last. This commitment to quality not only minimizes maintenance issues but also ensures consistent, high-precision performance across all production environments.

Hicof’s solution spans the entire serialization process:

Hicof’s Pharma Serialization Solution offers a comprehensive suite of features designed to address every aspect of pharmaceutical serialization.

Real-Time Data Capture

Monitor every stage of your production and distribution process in real-time. Immediate data capture means quicker decision-making and faster response times to any issues that may arise.

End-to-End Traceability

Every product is tracked from the moment it leaves the production line until it reaches the end consumer. This full-chain traceability ensures that any issues can be quickly identified and resolved, minimizing risk and enhancing patient safety.

Automated Workflows

Our Pharma Serialization Solution automates routine tasks such as data entry, reporting, and compliance checks. This automation reduces human error and frees up your staff to focus on more strategic activities.

Advanced Analytics & Reporting

Transform raw data into actionable insights with our advanced analytics tools. Detailed reports help you optimize production schedules, manage inventory more effectively, and improve overall operational efficiency.

Seamless Aggregation

Hicof’s Pharma Serialization Solution supports serialization at every level—from individual units to full pallet aggregation. This comprehensive approach ensures that every stage of the supply chain is documented and secure.

User-Friendly Interface

Our intuitive user interface minimizes the learning curve, allowing your team to quickly adapt to the new system. Clear dashboards, detailed reports, and easy navigation mean that everyone—from operators to managers—can work more efficiently.

Seamless Partner Integration

Designed to work not only within your organization but also with your entire supply chain, Hicof’s solution facilitates smooth data exchange with distributors, logistics providers, and regulatory agencies.

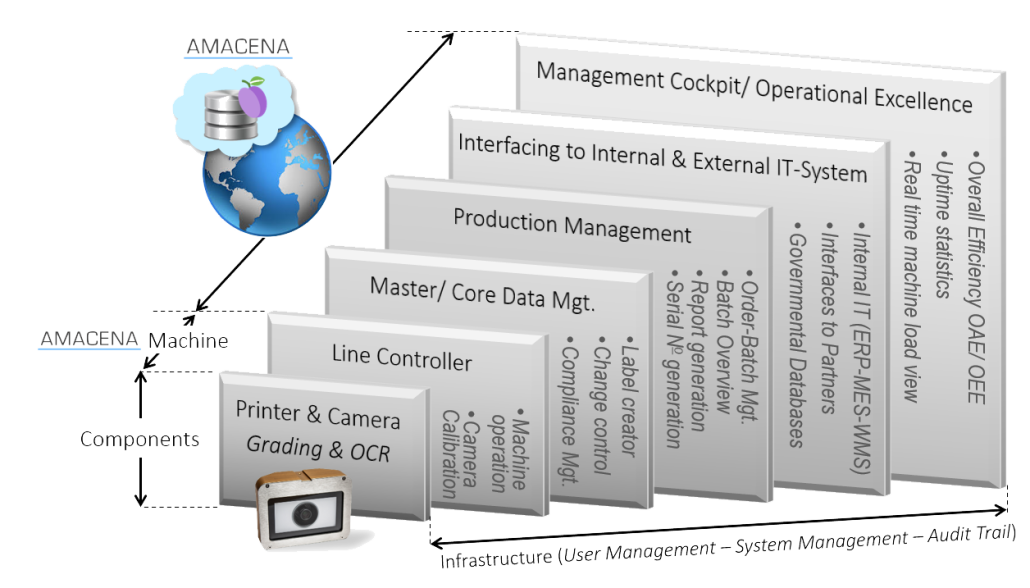

Hicof AMACENA is a uniform system covering all serialization related topics in the enterprise. The solution works as monoblock which allows the customer to use the same user interfaces across AMACENA. This reduces efforts in training and operations.

The HICOF Machines offer in combination with AMACENA an integrated IT-backbone, starting at machine level from the devices as printers, cameras and sensors up to data interfaces of governmental servers. In case of an issue, our experts have instantaneously access through remote access to all relevant parameters across all IT-servers down to the PLC, allowing a seamless and immediate support. This is the opposite of the conventional ISA-95 environment with several software and machine suppliers in which each service engineer has only access to his fraction of data, making a comprehensive root cause analysis extremely cumbersome as he has to synchronize with other involved vendors.

Hicof solves the issue by offering

One System, One Supplier, One Responsibility!