In an increasingly complex supply chain environment, efficient packaging and seamless traceability are essential for operational success. Hicof provides fully integrated solutions that streamline packaging processes while ensuring complete visibility and control over product movement. Our advanced systems combine high-performance machinery with intelligent software, creating a robust foundation for automation, accuracy, and compliance.

Hicof’s Track & Trace solutions provide real-time visibility and seamless product traceability across the entire supply chain. With integrated aggregation software and automated data capture, they enhance security and regulatory compliance. Easy to implement, our systems help businesses streamline operations and protect product integrity.

Hicof’s packaging solutions combine efficiency, precision, and automation to optimize production workflows. Our compact and robust casepackers ensure secure packaging while integrating seamlessly into various production environments. Designed for easy maintenance and high performance, they help businesses scale with confidence.

Hicof’s packaging solutions are designed to optimize efficiency, minimize downtime, and enhance overall productivity. Our automated systems ensure that products are securely packed, reducing errors and improving consistency across production lines. Whether the need is for semi-automatic or fully automated case packing, our machines provide:

Traceability is a critical component of modern supply chains, ensuring that every product can be tracked from its origin to its final destination. Hicof’s Track & Trace solutions leverage cutting-edge technology to provide full visibility into every step of the process. With built-in aggregation software, our systems enable:

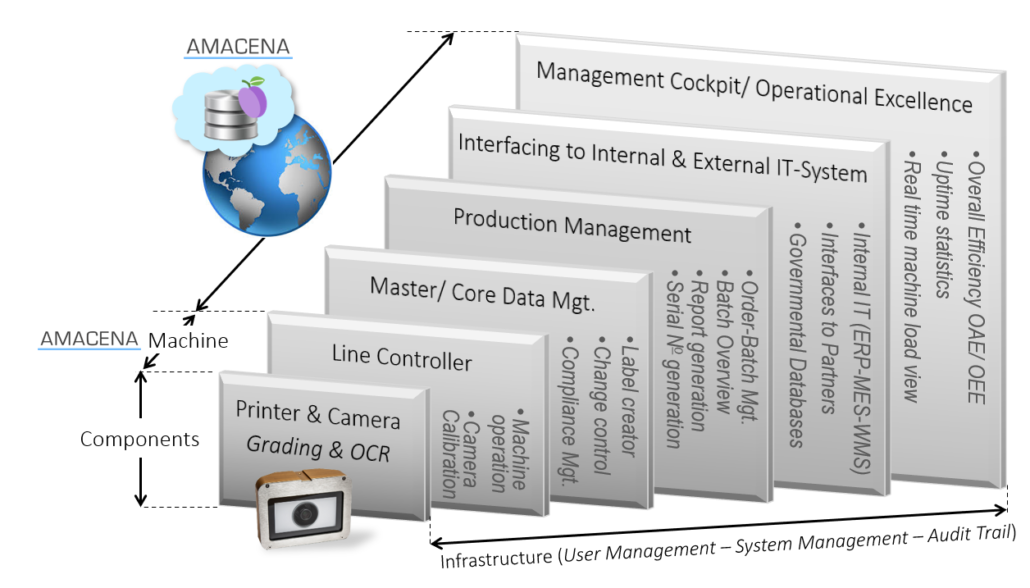

Hicof AMACENA is a uniform system covering all serialization related topics in the enterprise. The solution works as monoblock which allows the customer to use the same user interfaces across AMACENA. This reduces efforts in training and operations.

At the core of Hicof’s solutions is intelligent software that unifies packaging and traceability into a single, cohesive system. This software provides:

Hicof goes beyond simply providing technology—we ensure that every solution is seamlessly implemented and continuously optimized. Our approach includes:

By choosing Hicof, businesses gain a future-proof solution that enhances efficiency, security, and compliance. Our integrated approach to packaging and traceability delivers:

With Hicof’s commitment to quality and innovation, businesses can streamline operations, enhance traceability, and ensure compliance—all while preparing for future growth. Get in touch today to explore the possibilities.

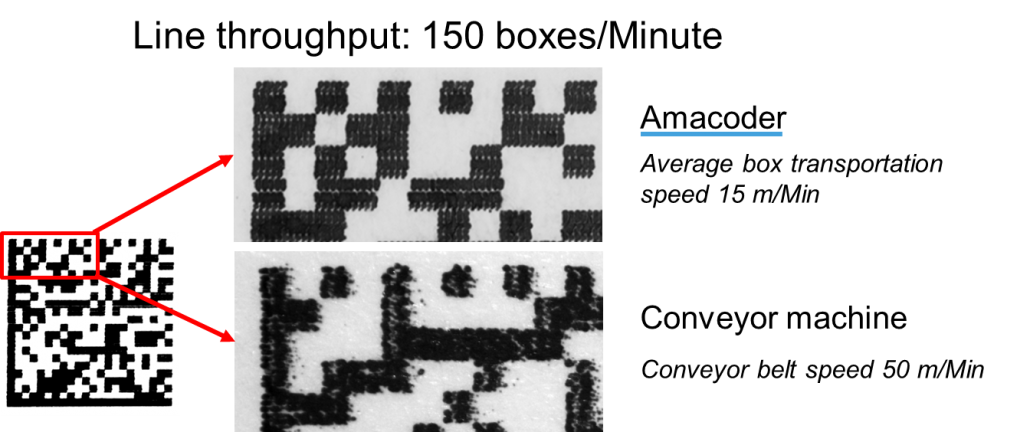

The Amacoder delivers a very high coding quality as shown in the image.

The reason for this high coding quality is as follows:

The HICOF Machines offer in combination with AMACENA an integrated IT-backbone, starting at machine level from the devices as printers, cameras and sensors up to data interfaces of governmental servers. In case of an issue, our experts have instantaneously access through remote access to all relevant parameters across all IT-servers down to the PLC, allowing a seamless and immediate support. This is the opposite of the conventional ISA-95 environment with several software and machine suppliers in which each service engineer has only access to his fraction of data, making a comprehensive root cause analysis extremely cumbersome as he has to synchronize with other involved vendors.

Hicof solves the issue by offering

One System, One Supplier, One Responsibility!