The Hicof HECTOR system allows to easily integrate track and trace and quality control capabilities to any industrial machine. The system is deeply integrated to the Hicof AMACENA Software which allows managing your aggregation and serial data across the enterprise.

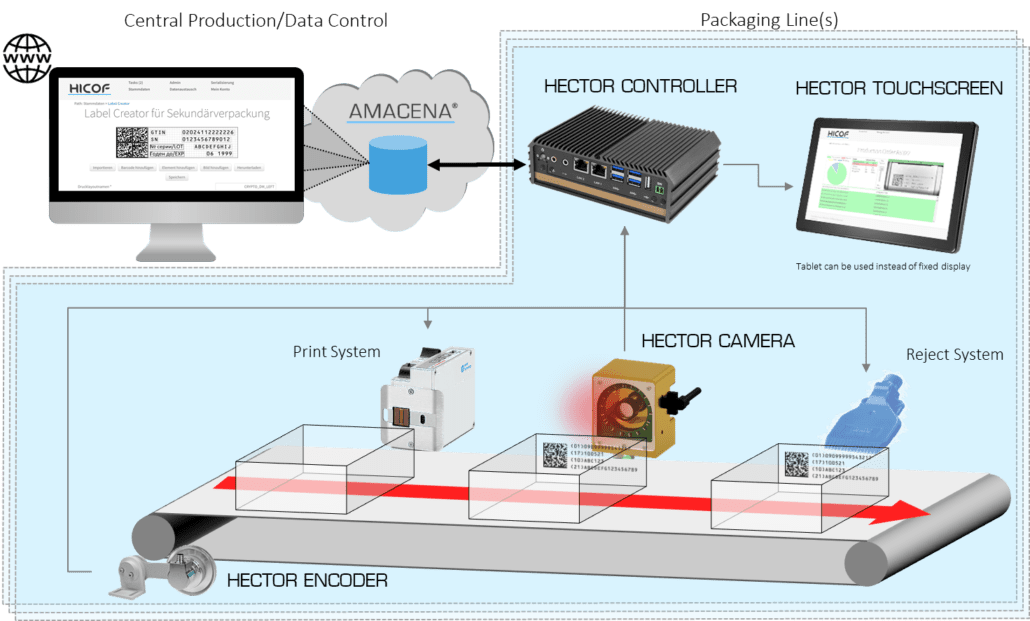

Hicof HECTOR Serialization Hardware Kit can be integrated on any machine to manage the process of serial numbering with variable printing systems as e.g. Thermo Inkjet, Continuous Inkjet or Laser Printing. HECTOR includes a customisable kit of Hardware components which are all connected to the HECTOR Controller as central orchestrator of the machine. The Controller can be connected to the HECTOR Cameras which allows to perform print inspection according ISO15415 and OCR as well as to rejection systems. Additionally, HECTOR has an integrated register function which allows it to track the product through the machine based on encoder signals.

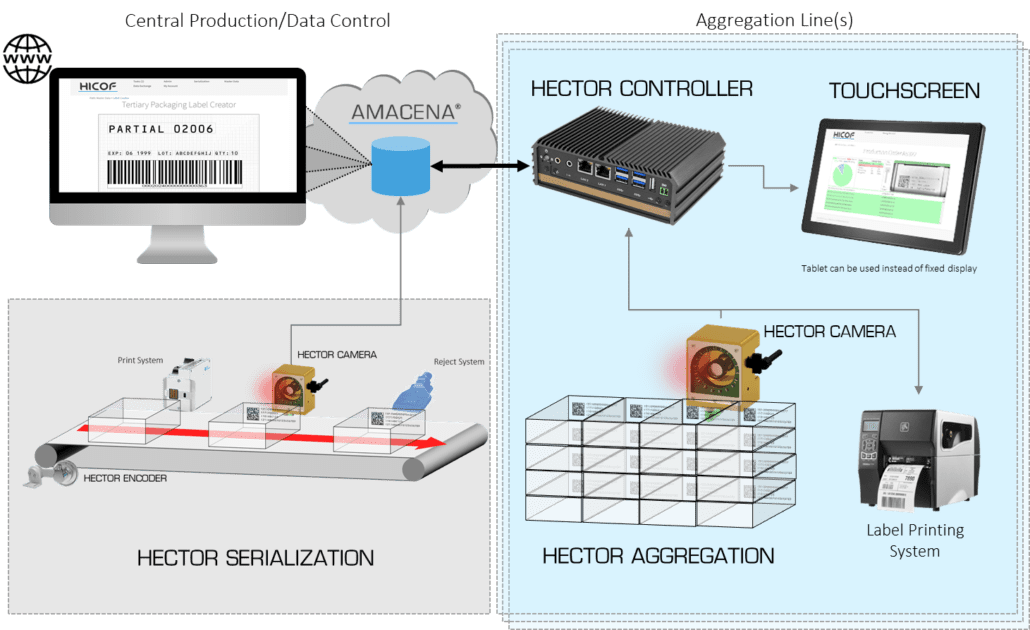

Beside Serialization the HECTOR Serialization Hardware Kit can be used to manage the process of aggregation of serialised products. HECTOR includes a customisable kit of Hardware components which are all connected to the HECTOR Controller as central orchestrator of the machine. The Controller is connected to the HECTOR Camera which allows to perform aggregation over multiple packaging levels thanks to a wide variety of optical systems. HECTOR can also be connected to Label printing systems as e.g. Thermal Transfer printers to create the individual identifier of the aggregated container.

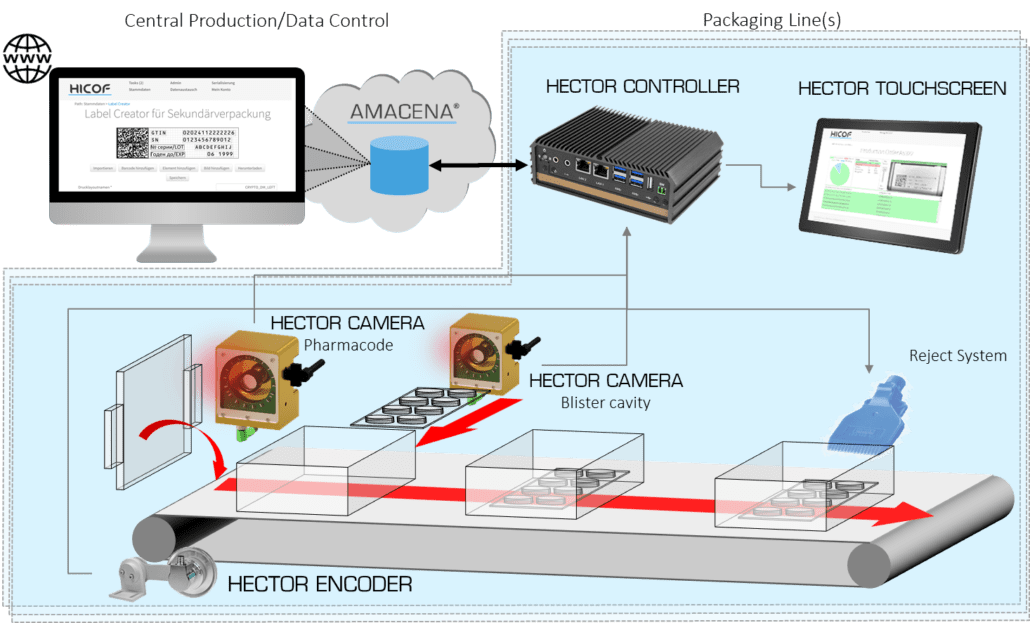

Finally, HECTOR can be integrated into any machine to manage the process of visual quality inspection as e.g. Pharmacode reading, filling control of Blister cavities, quality inspection of tablets, quality inspection of moulded products. HECTOR includes a customisable kit of Hardware components which are all connected to the HECTOR Controller as central part of the machine. The Controller is connected to the HECTOR Camera which allows to perform a wide range of quality inspections as well as to rejection systems. With its integrated register function HECTOR can track the product through the machine based on encoder signals.

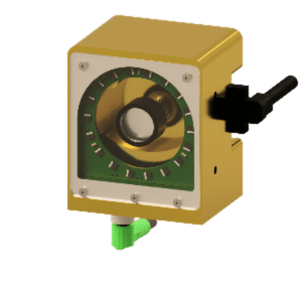

The HECTOR Serialization Hardware Kit – Cameras are based on a modular system which allows to customise the camera to the requirements of the individual application. Some of the general specifications that are available:

The HECTOR Serialization Hardware Kit – Controller is at every installation the core which hosts the databases and the user interfaces of all attached components. The controller is typically specified according to the requirements. Some of the general specification that are available:

Hicof can offer stand-alone Touchscreens for the HECTOR Serialization Hardware Kit . Alternatively, the application can run on existing HMI’s as Web-App. The standard monitors start at 15.6 inch size and can be customised to the requirements of the application.

Hicof AMACENA features a build-in web based label creator to create and adjust all print layouts for HECTOR systems, AMACODERS, and all connected tertiary label printers. The label creator allows GMP compliant change control of all label parameters across the enterprise.

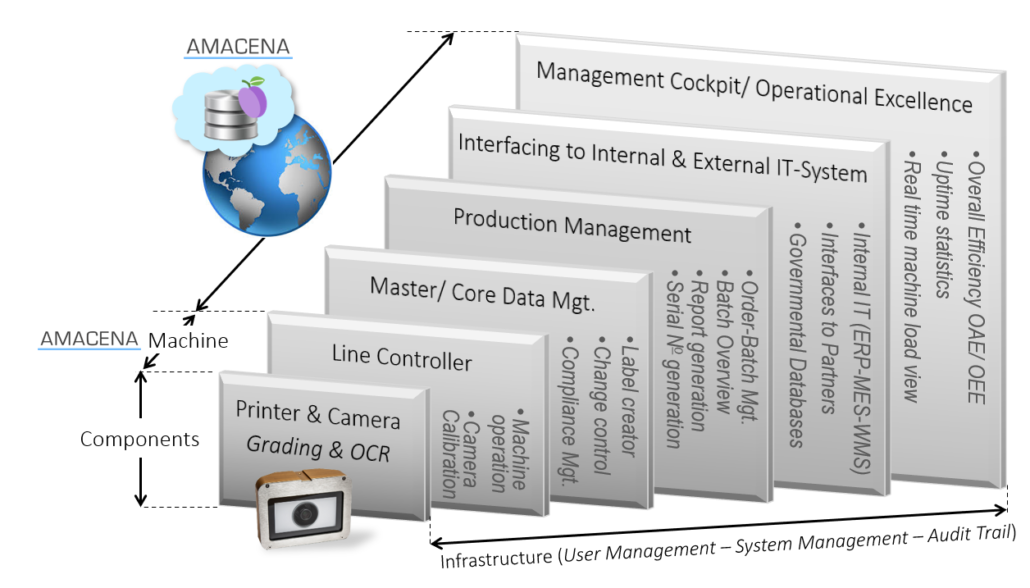

Hicof AMACENA is a uniform system covering all serialisation related topics in the enterprise. The solution works as monoblock which allows the customer to use the same user interfaces across AMACENA. This reduces efforts in training and operations.

The HICOF Machines offer in combination with AMACENA an integrated IT-backbone, starting at machine level from the devices as printers, cameras and sensors up to data interfaces of governmental servers. In case of an issue, our experts have instantaneously access through remote access to all relevant parameters across all IT-servers down to the PLC, allowing a seamless and immediate support. This is the opposite of the conventional ISA-95 environment with several software and machine suppliers in which each service engineer has only access to his fraction of data, making a comprehensive root cause analysis extremely cumbersome as he has to synchronize with other involved vendors.

Hicof solves the issue by offering

One System, One Supplier, One Responsibility!