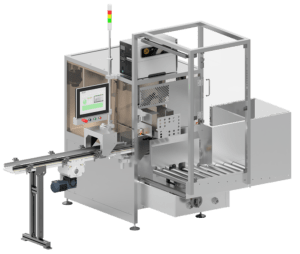

The AMAPACKER as a semi-automatic casepacker which automatically loads cartons or bundles in one or more layers into pre-formed shipping cases placed in position by an operator. One operator can pack up to 150 boxes per minutes and at the same time all aggregation processes are done by the machine in the background.

The AMAPACKER as a semi-automatic case packer which automatically loads cartons or bundles in one or more layers into pre-formed shipping cases placed in position by an operator. Thereby the machine follows an innovative ergonomic concept which allows effortless operation. One operator can pack up to 150 boxes per minutes and at the same time all aggregation processes are done by the machine in the background. It is the most economical way to automate the packaging process and at the same time fulfilling the legally required aggregation process.

The AMAPACKER is a completely new design, integrating robust machinery powered by high-end servo drives with the complete aggregation equipment. The machine is fully built in stainless steel (stainless tube frame) and aluminium according highest design standards. The machine has a very small footprint and is therefore also useable for retrofitting existing packaging lines. Operation of the AMAPACKER is economical as the machine consumes only a small volume of compressed air and very few and low-cost format parts. The format change can be carried out within a very short amount of time and without tools. The machine can be equipped with a variety of infeed and outfeed options including automatic labelling and sealing of the finished shipping cases.

The AMAPACKER S150 offers within the standard the capability for aggregation. Therefore, the casepacker offers the ideal balance between packaging efficiency and short changeover times.

The AMAPACKER 150 is the baseline casepacker which offers the ideal balance between packaging efficiency and short changeover times. The machine is prepared to be easily equipped with the necessary equipment for aggregation.

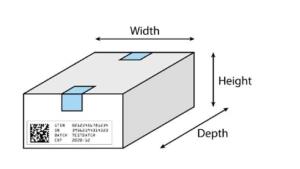

Legend Folding Box

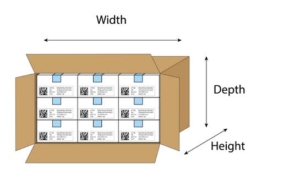

Legend Shipping Case

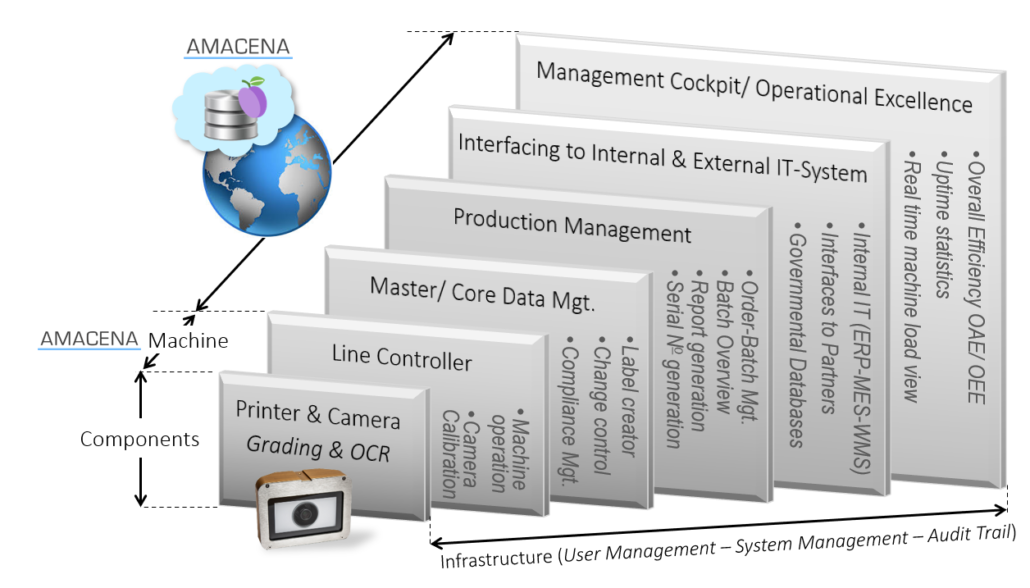

Hicof Amacena features a build-in web based label creator to create and adjust all print layouts for AMACODERS, and all connected tertiary label printers. The label creator allows GMP compliant change control of all label parameters across the enterprise.

Hicof AMACENA is a uniform system covering all serialization related topics in the enterprise. The solution works as monoblock which allows the customer to use the same user interfaces across AMACENA. This reduces efforts in training and operations.

Hicof AMACENA allows to integrate the solution with in-house IT, external partners and governmental systems. The solution features an easy to use interface engine to quickly set new connections. AMACENA is build around the EPCIS standard of GS1 which allows seamless integration with the majority of systems on the market.

The HICOF Machines offer in combination with AMACENA an integrated IT-backbone, starting at machine level from the devices as printers, cameras and sensors up to data interfaces of governmental servers. In case of an issue, our experts have instantaneously access through remote access to all relevant parameters across all IT-servers down to the PLC, allowing a seamless and immediate support. This is the opposite of the conventional ISA-95 environment with several software and machine suppliers in which each service engineer has only access to his fraction of data, making a comprehensive root cause analysis extremely cumbersome as he has to synchronize with other involved vendors.

Hicof solves the issue by offering One System, One Supplier, One Responsibility!