The Ivers-Lee Group is one of the leading contract packagers in Switzerland. Founded almost 100 years ago, the group of companies is a family business in its third generation, led by Dr. Ing. ETH Peter Schüpbach and his management team. In order to be able to use the available resources optimally from an organizational point of view, Ivers-Lee transformed the classic department-oriented workflow into a process-based organization. This not only ensures a high degree of flexibility in the packaging processes, but also improves quality and minimizes costs.

Sascha Toedtli, CEO of Hicof AG, characterizes his company as follows: “We offer integrated complete systems, based on innovative and patented concepts, built in a combination of robust mechanics and software-supported motion sequences. Thus, our products have an attractive price-performance ratio despite high functionality and quality.”

In a process-oriented organization, weak points in the workflow become neuralgic bottlenecks, at Ivers-Lee this was the case with serialization. Regardless the fact, that equipment and software from renowned manufacturers were installed, that infrastructure did not perform as planned. In particular, the service was unsatisfactory because several suppliers were engaged with their products. The fact that the IT-architecture was based on the today outdated ISA-95 principles proved to be a particularly problematic as it required interfaces between the software packages, some of which were manual and complicated. The associated investments and operating costs subsequently became uncontrollable. To remedy these shortcomings, the following requirements were specified regarding the replacement system: The successor serialization landscape, machines and software should be supplied from only one supplier. Ideally, the new system should no longer have an ISA-95 architecture; instead, an integrated, cloud (personalized Ivers-Lee instance) based software is required. Furthermore, the printer and control camera should be set automatically for each new print job. Another key requirement is an excellent code print quality as a result of precise alignment and guidance of the folding cartons in the line to ensure low ejection rates.

The selected system, consisting of software, coding as well as semi-automatic aggregation line was supplied by the Swiss company Hicof AG.

The backbone of the new serialization system is the integrated standard software AMACENA, which covers all functionalities of conventional level 1 to level 4 architectures in full granularity. In addition to cost advantages, it is pre-validated as standard software, which largely eliminates the need for classic validation, also known as CSV.

AMACENA offers additionally the following advantages: Since the software and the machines form an integrated system, Hicof can access all current and historical data down to the PLC via “remote access” in the event of support, which ensures an efficient solution to any issues.

All master data are managed in a single, central cluster of the system and are therefore easy to maintain. Costly and error-prone master data reconciliation between different IT serialization systems no longer exists. Typical master data, such as the Artwork to be printed, i.e. settings for the printer and the quality assessment camera, are created centrally in the customers office on AMACENA by “drag & drop”. This artwork is then automatically assigned to the corresponding print jobs. Settings on the printer and camera directly on the lines are no longer required.

Modifications to master data and other important information is made according to GxP rules. This means that a copy of the original record is created for correction, after modification the updated record is submitted via AMACENA software to a second person/institution for approval. After acceptance of the modification, the corrected value replaces the existing data. Such changes are also documented simultaneously in the audit trail. Manual data change GxP documentation is no longer required.

Christian Stifter, project manager for serialization at Ivers-Lee, cites “The integrated AMACENA software is one of the key advantages of Hicof systems. The software provides direct online access to practically all relevant data, from machine/PLC level right up to corporate level 4, in the event of servicing. This means that faulty manipulations and any malfunctions can be quickly identified and rectified.”

Hicof Amacena features a build-in web based label creator to create and adjust all print layouts for AMACODERS, and all connected tertiary label printers. The label creator allows GMP compliant change control of all label parameters across the enterprise.

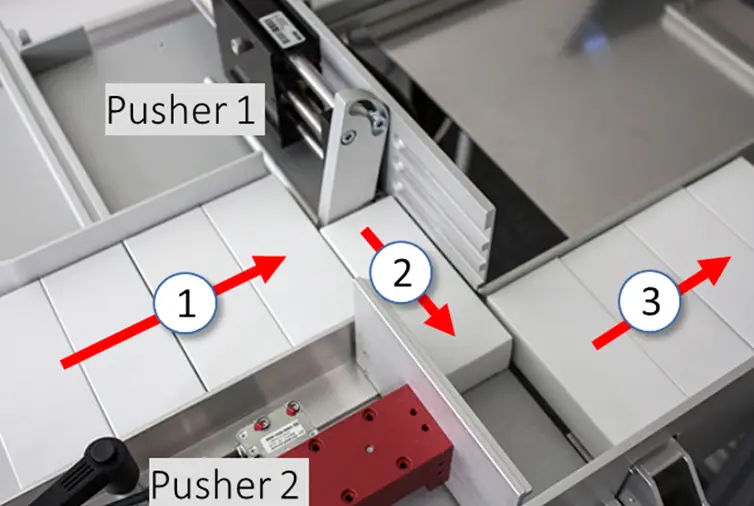

The three Hicof AMACODER coding lines at Ivers-Lee operate on an innovative, unique principle. Instead of conveyor belts, a sliding mechanism moves the boxes through the machine. This ensures that the folding boxes to be coded are correctly aligned and conveyed through the line with high precision. Barcode qualities in the A and B range according to ISO 15415 are the rule, not the exception. Few, simple, moving components guarantee modest maintenance costs. The coding and aggregation lines as well as the Hicof shipping carton packers are directly controlled by AMACENA. In case of Internet connection interruptions, all Hicof coding and aggregation machines continue to operate autonomously and data is automatically synchronized when the connection is re-established.

Dr. Peter Schüpbach, Managing Director and owner of Ivers-Lee: “The ever-smaller order sizes call for the use of semi-automatic machines and systems. Consequently, Ivers-Lee ordered the semi-automatic Hicof AMAPACKER-S150 which, in addition to packing the shipping cartons, also takes over the aggregation of the serialized folding cartons. As the AMAPACKER also packs automatically the boxes, a rationalization effect results in cutting costs significantly.”

Another remarkable increase of process efficiency for Ivers-Lee was the possibility of exchanging serial data directly with Ivers-Lee customers via AMACENA without requiring additional Level 4 software from a third-party manufacturer. In summary, Ivers-Lee sums up the experience to date

Dr. Peter Schüpbach, Managing Director and owner of Ivers-Lee: “The previous serialization software systems and coding lines were replaced by Hicof in a timely manner within the specified, extended technical and functional performance parameters without any problems. The Hicof infrastructure is proving to be reliable, cost-effective and much easier to operate. Ivers-Lee considers Hicof as a partner in the field of systems for end-of-line packaging and will continue to count on their good services.”