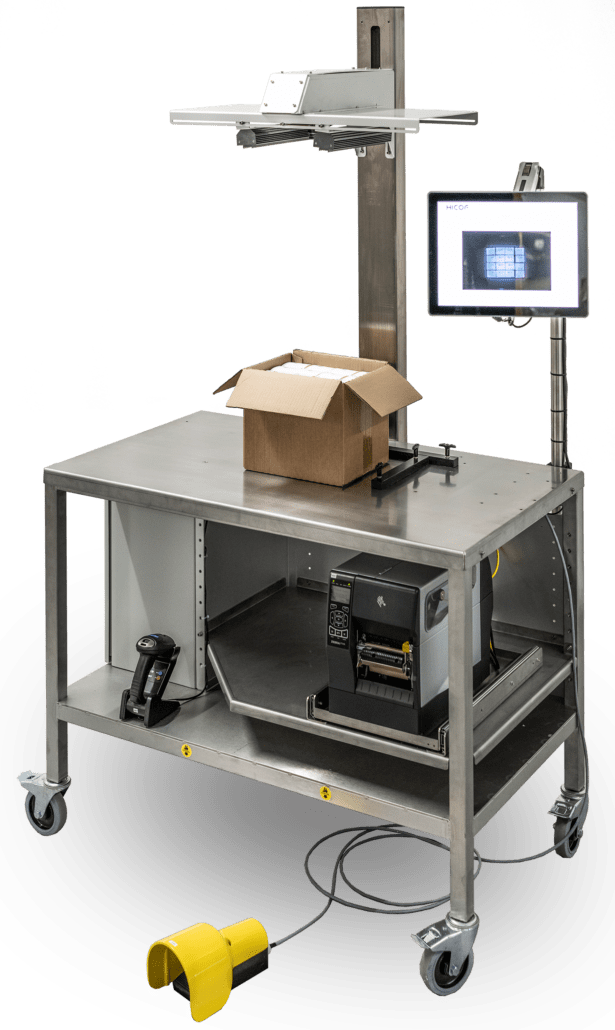

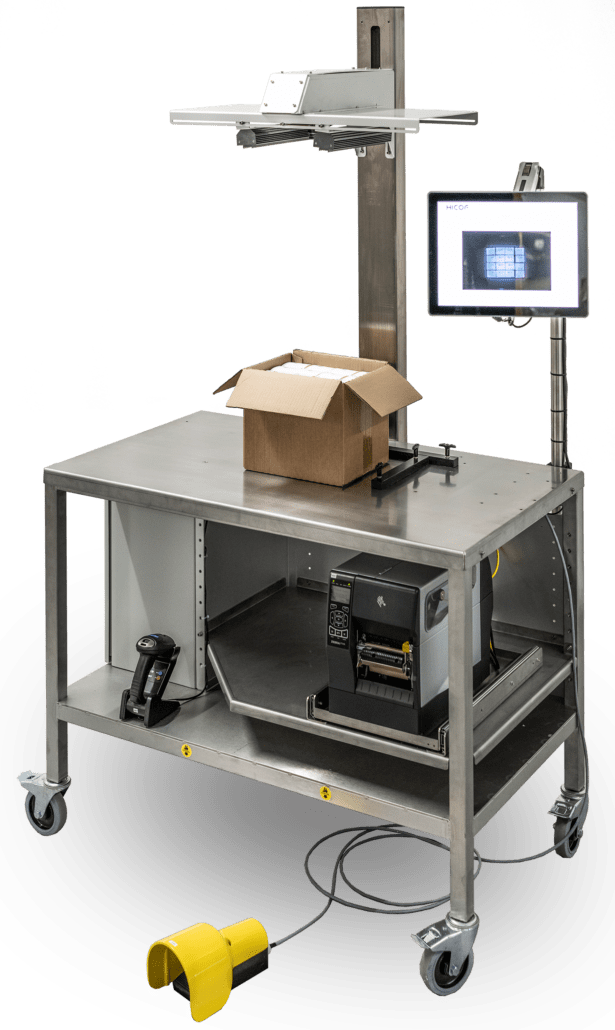

The Hicof AMAJOINERS are manual aggregation stations. Some of them are equipped with a high resolution overhead camera for efficient manual aggregation. This allows low cost aggregation of serialized products to shipping cases and pallets.

The AMAJOINER is a mechanically separate machine which can operate as stand-alone unit or in direct connection with a Hicof coding line. The AMAJOINER reads the serial codes printed on the folding boxes when they are placed into the shipping carton. With an overhead camera or manually with a handscanner all codes in a packaging layer are scanned. The system checks also if the quantity of the boxes is correct according the packaging scheme. With this procedure, the risk of errors is minimised. If several layers of folding boxes are placed in the shipping carton, the scanning process has to be repeated layer by layer.

As user of the AMAJOINER you can profit from the following advantages:

The AMAJOINER 10 offers manual aggregation capabilities for warehouses and production lines. The machine is housed in a stable stainless table and can hold up to two thermo-transfer printers.

The AMAPACKER S150 offers within the standard the capability for aggregation. Therefore, the casepacker offers the ideal balance between packaging efficiency and short changeover times.

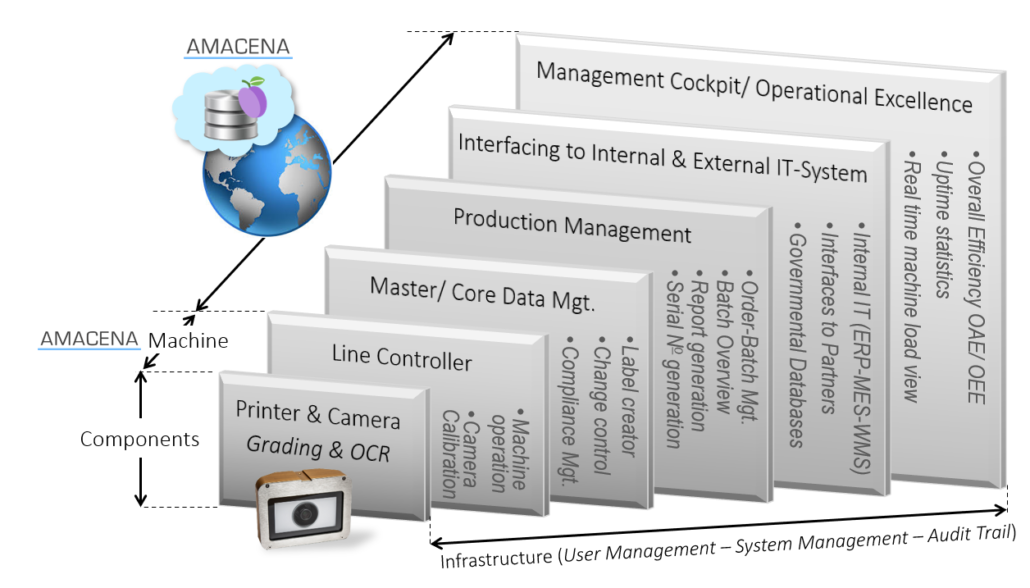

Hicof AMACENA is a uniform system covering all serialization related topics in the enterprise. The solution works as monoblock which allows the customer to use the same user interfaces across AMACENA. This reduces efforts in training and operations.

Hicof AMACENA allows to integrate the solution with in-house IT, external partners and governmental systems. The solution features an easy to use interface engine to quickly set new connections. AMACENA is build around the EPCIS standard of GS1 which allows seamless integration with the majority of systems on the market.

The HICOF Machines offer in combination with AMACENA an integrated IT-backbone, starting at machine level from the devices as printers, cameras and sensors up to data interfaces of governmental servers. In case of an issue, our experts have instantaneously access through remote access to all relevant parameters across all IT-servers down to the PLC, allowing a seamless and immediate support. This is the opposite of the conventional ISA-95 environment with several software and machine suppliers in which each service engineer has only access to his fraction of data, making a comprehensive root cause analysis extremely cumbersome as he has to synchronize with other involved vendors.

Hicof solves the issue by offering:

One System, One Supplier, One Responsibility!